OUR CLIENTS

Once we have received product development briefing, we thoroughly understand your unique requirements, performance objectives, and application-specific challenges. Through rigorous assessment, our experienced team identifies technical specifications, feasibility, and potential improvements, setting the foundation for precision-engineered solutions that precisely meet your business needs, timelines, and quality standards.

Our innovative design phase blends advanced German engineering techniques with state-of-the-art digital tools like Pro-Engineer Creo and AutoCAD. We develop detailed, optimized designs ensuring exceptional performance, durability, and compatibility with your systems. Our cross-functional team collaborates closely to integrate manufacturing insights, ensuring designs are both innovative and practically aligned with production capabilities and market demands.

Prototype development transforms our detailed designs into tangible models, allowing real-world evaluation and refinement. Utilizing our advanced in-house tool room and precision manufacturing capabilities, we rapidly produce accurate prototypes. These prototypes undergo rigorous initial testing, enabling early identification of potential improvements or adjustments—ensuring final products deliver optimal performance, durability, and reliability in their intended environments.

Performance testing and validation confirm that each product meets stringent quality standards. Our fully equipped laboratory conducts extensive material, mechanical, and operational tests—including hardness, durability, load-bearing capability, and lifecycle testing. Adhering to international standards (IATF 16949), our validation processes guarantee that products consistently meet real-world demands, ensuring reliability, safety, and peak performance across diverse and challenging applications.

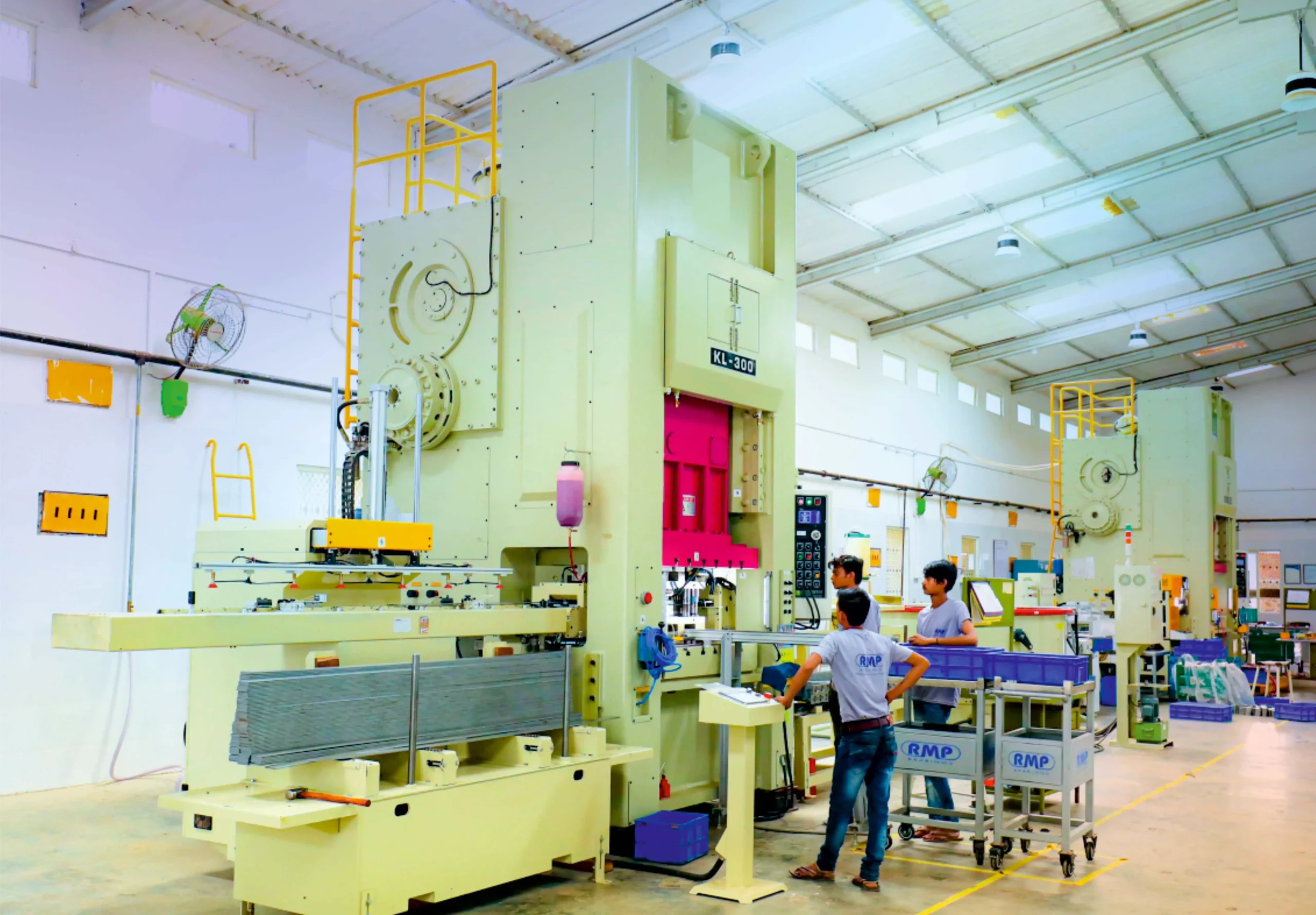

During serial production, we maintain strict continuous quality control and monitoring systems. Our state-of-the-art facilities employ Industry 4.0 technologies—process automation, advanced equipment monitoring, and real-time operational analytics—to swiftly identify and correct deviations. This meticulous approach ensures consistent high-quality manufacturing, reduced variability, and completion of every batch within the designated timeframe, solidifying our promise of excellence and professionalism.